Columnar to equiaxed transformation in TiAl based alloys

Summary

The crucial problem of precise casting of TiAl turbine blades or turbocharger wheels is transformation of columnar grain structure to equiaxed one. This transformation leads to a significant microstructure inhomogeneity which cannot be removed by the heat treatments. Therefore, large interest in the research is paid to explanation of mechanisms of columnar to equiaxed transformation (CET) in TiAl alloys based on experimental studies at controlled solidification conditionsin Bridgman type apparatus supported by numerical modelling of local solidification parameters.Objectives

- Steady state growth to study the effect of constant growth parameters on microstructure of TiAl based alloys.

- Non-steady state growth for achieving CET during directional solidification of cylindrical samples by continuous change of growth rate and temperature gradient in liquid.

- Development of “power down technique” for obtaining CET in cylindrical samples by a continuous decrease of temperature in Bridgman type apparatus.

- Development of methodology for reliable determination of the position of CET in TiAl based alloys undergoing several solid phase transformations of primary solidification phase during cooling.

Achievements

- Steady state growth at constant growth rate and constant temperature gradient in liquid leads either to the growth of columnar or equiaxed lamellar grains within the cylindrical samples.

- Non-steady state growth achieved by a continuous change of the growth rate and temperature gradient in liquid leads to the growth of columnar grains which transform to equiaxed ones after achieving critical local growth parameters.

- The first CET diagram based on experimental data from directional solidification at the steady and non-steady state growth conditions was defined.

- The effect of constant cooling rate on the position of CET in cylindrical samples was determined by “power down technique”.

- Local growth rates and temperature gradients required for CET were numerically calculated using temperate profiles and boundary conditions measured experimentally during “power down technique”. Numerical multi-scale 2D model of microstructure formation during solidification, specifically for use with the experimental Bridgman type apparatus was developed and experimentally verified.

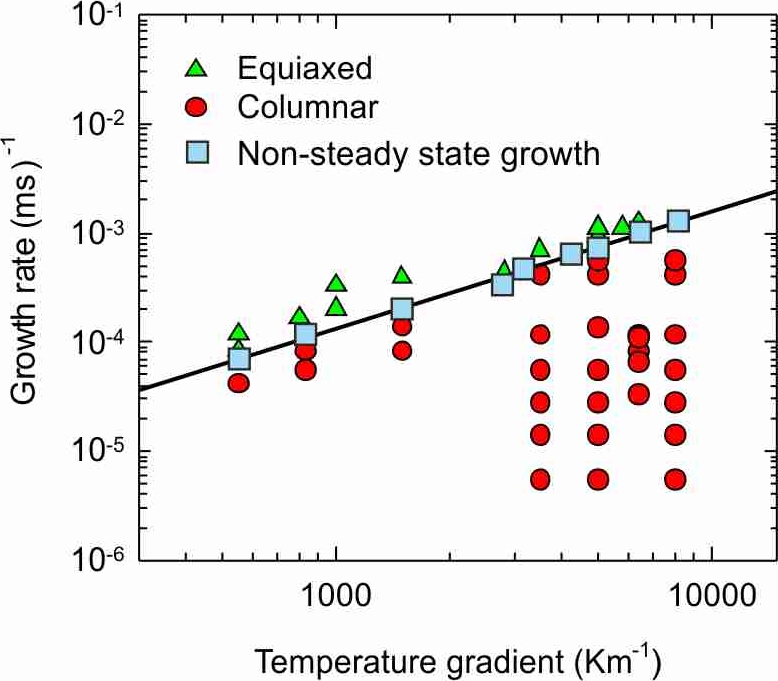

Experimentally determined CET diagram of intermetallic Ti-46Al-8Nb (at.%) alloy

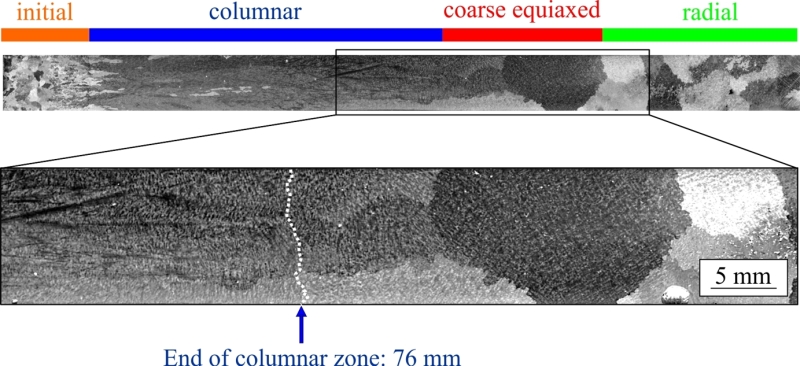

Experimentally determined CET diagram of intermetallic Ti-46Al-8Nb (at.%) alloy Macrostucture of a CET sample prepared by power-down technique

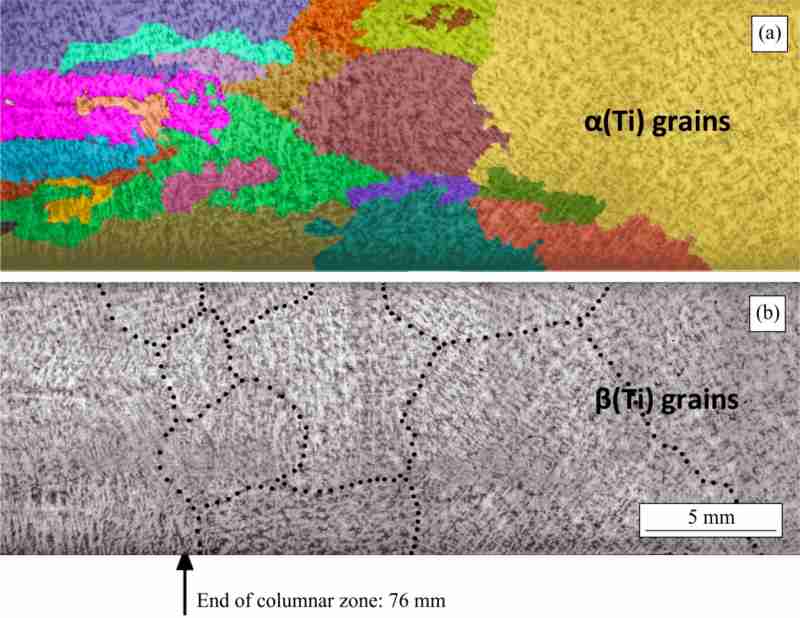

Macrostucture of a CET sample prepared by power-down technique Grain structure of a CET sample prepared by power-down technique: (a) resulting map showing the α(Ti) grains, (b) columnar and equiaxed zones in the vicinity of the CET

Grain structure of a CET sample prepared by power-down technique: (a) resulting map showing the α(Ti) grains, (b) columnar and equiaxed zones in the vicinity of the CETAdditional reading

MOONEY, R. P. - HECHT, U. - GABALCOVÁ, Z. - LAPIN, J. - MCFADDEN, S. Directional solidification of a TiAl alloy by combined Bridgman and power-down technique. In KOVOVE MATER, 2015, vol.53,pp. 187-197.(IF 0.356) (Current Contents, Scopus, WOS). ISSN 0023-432X.MOONEY, R. P. - LAPIN, J. - KLIMOVÁ, A. - McFADDEN, S. Conditions for CET in a gamma TiAl alloy. In IOP Conf. Series: Materials Science and Engineering, 2015, vol.84, Article number: 012088, 8 p. (Scopus, WOS). ISSN: 1757-8981.

LAPIN, J. - GABALCOVÁ, Z. - HECHT, U. - MOONEY, R. P. - McFADDEN, S. Columnar to equiaxed transition in peritectic TiAl based alloy studied by a power-down technique. In MATER SCI FORUM, 2014, vols.790-791, pp. 193-198. (Scopus). ISSN: 0255-5476.

MOONEY, R. P. - McFADDEN, S. - GABALCOVÁ, Z. - LAPIN, J. An experimental-numerical method for estimating heat transfer in a Bridgman furnace. In APPL THERM ENG, 2014, vol.67, pp. 61-71. (IF 2.739) (Scopus, WOS). ISSN: 1359-4311.

LAPIN, J. - KLIMOVÁ, A. - GABALCOVÁ, Z. Effect of columnar to equiaxed transition on microsegregation behaviour of main alloying elements in peritecticTiAl-based alloy. In KOVOVE MATER, 2013, vol. 51, pp. 147-154. (IF 0.546). (Current Contents, WOS, SCOPUS). ISSN 0023-432X.

LAPIN, J. - GABALCOVÁ, Z.Solidification behaviour of TiAl-based alloys studied by directional solidification technique. In INTERMETALLICS, 2011, vol.19, pp. 797-804. (IF 1.649) (Current Contents, Scopus, WOS). ISSN: 0966-9795.

LEMOISSON, F. - McFADDEN, S. - REBOW, M. - BROWNE, D.J. - FROYEN, L. - VOSS, D. - JARVIS, D.J. - KARTAVYKH, A. - REX, S. - HERFS, W. - GROTHE, D. - LAPIN, J. - BUDENKOVA, O. - ETAY, J. - FAUTRELLE, Y. The development of a microgravity experiment involving columnar to equiaxed transition for solidification of a Ti-Al based alloy. In MATER SCI FORUM, 2010, vol. 649, pp. 17-22.(Scopus,WOS). ISSN: 0255-5476.

GABALCOVÁ, Z. - LAPIN, J. Experimental study of columnar to equiaxed transition during directionals olidification of intermetallic Ti-46Al-8Nb alloy. In 18th International Conference on Metallurgy and Materials, METAL 2009. 2009, Červený zámek, Hradec nad Moravicí, Tanger Ltd, 6p.(Scopus,WOS). ISBN 978-80-87294-03-1.

HECHT, U. - DALOZ, D. - LAPIN, J. - DREVERMANN, A. - WITUSIEWICZ, V. T. - ZOLLINGER, J. Solidification of TiAl-based alloys. In: Mater. Res. Soc. Symp. Proc., 2009, vol.1128, pp. 79-90.(Scopus,WOS). ISSN: 0272-9172, ISBN: 978-1-60511-1001.

Súvisiace projekty

- Intermetalické zliatiny na báze TiAl pre aplikácie v automobilovom a energetickom priemysle, 2013 - 2015

- Kryštalizácia a vlastnosti nových peritektických zliatin na báze TiAl, 2011 - 2014

- Gravitačná závislosť prechodu kolumnárnych zŕn na rovnoosé v peritektických zliatinách na báze TiAl, 2010 - 2017

- Metalurgická príprava a výskum nových intermetalických materiálov pre extrémne podmienky namáhania, 2008 - 2010

- Výroba intermetalických materiálov v spojitosti s ich kryštalizáciou na Zemi a v kozme, 2004 - 2009