Nové materiály / Ľahké materiály / Kompozity s hliníkovou matricou /

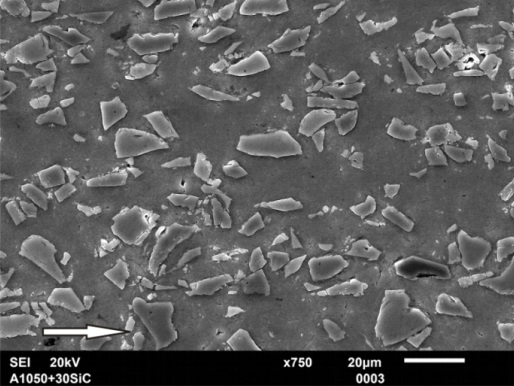

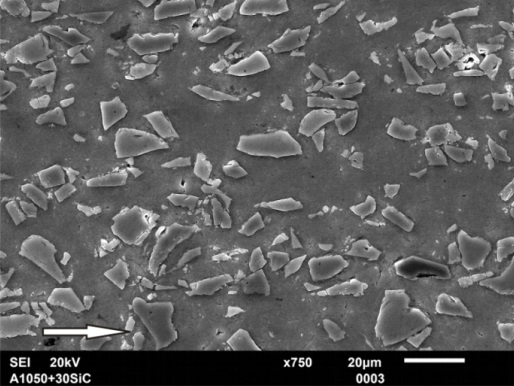

SEM micrograph of A1050 + 30 vol.% SiCp composite

SEM micrograph of A1050 + 30 vol.% SiCp composite

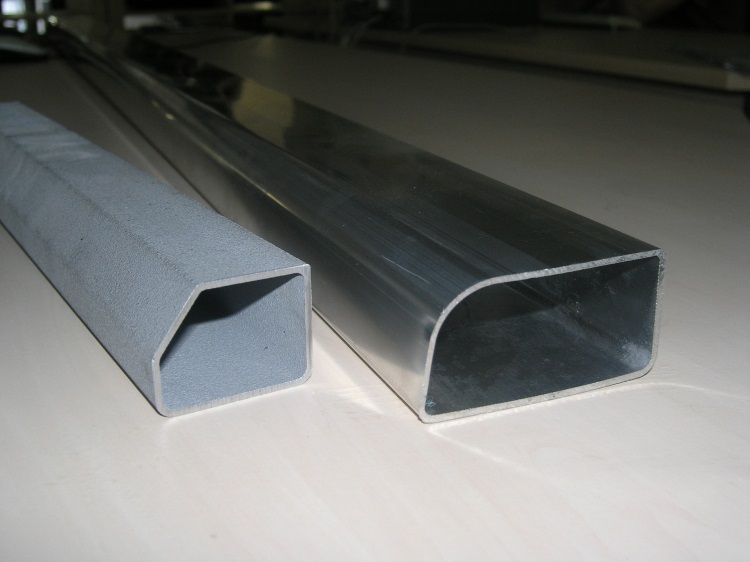

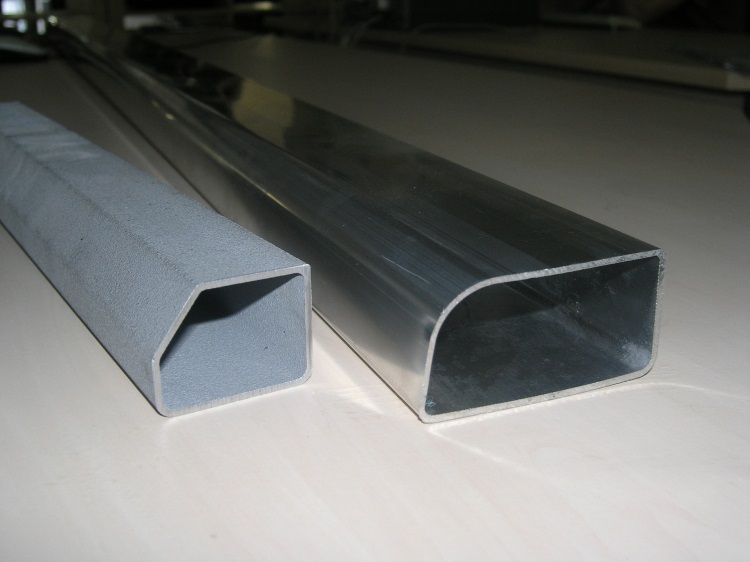

Extruded composite profiles for automotive industry

Extruded composite profiles for automotive industry

Extruded Al/SiC composites

General description:

Al profiles reinforced with small SiC particles are hot extruded from powder mixtures using standard aluminium alloy powders. The obtained geometry and complexity is similar to typical aluminium alloy profiles, nevertheless, due to the effect of ceramic particles, the profiles possess significantly higher specific stiffness and wear resistance. As a matrix, the standard wrought Al alloy powders (A2024, A3003, A5083, A6061, A7075) can be used. The volume content of small SiC particles can vary from 0 up to 40 % (typically 10 - 30 %).Typical properties

Al 5083 alloy composite reinforced with 20 vol.% of SiC particles:- young’s modulus (E): ~100 GPa

- density: ~2,6 g/cm3

- ultimate tensile strength UTS: ~400 MPa

- yield stress YS: ~330 MPa

- elongation to fracture A: ~4 %

- coefficient of thermal expansion CTE: ~ 17 ppm/K

Main benefits

Due to high Young’s modulus and low density of composites, the obtained profiles exhibit 50% higher specific stiffness if compared with conventional Al-alloy profiles. Beside this, the composites possess low CTE, high wear resistance and excellent structural stability at elevated temperatures. They are industrially produced using conventional hot extrusion, thus keeping the costs at a moderate level (<10 EUR/kg).Potential applications

Al/SiC composite profiles are successfully applied in lightweight construction, especially in stiffness limited design (car body frames, moving arms of robots, stiff lightweight structural struts, machine frames for precise cutting, welding machines, sports equipment, aerospace industry,..) wear resistant sliding profiles, or parts where lower CTE and high temperature stability is required. SEM micrograph of A1050 + 30 vol.% SiCp composite

SEM micrograph of A1050 + 30 vol.% SiCp composite Extruded composite profiles for automotive industry

Extruded composite profiles for automotive industry