Novel pressure assisted reactive synthesis for the preparation of functionally graded Mo/Mo silicide composites

Summary

Novel technique for the preparation of functionally graded Mo/Mo silicide composites has been developed and applied. The newly developed gradient Mo/MoxSiy composite exhibited outstanding high temperature oxidation resistance and mechanical properties.Objectives

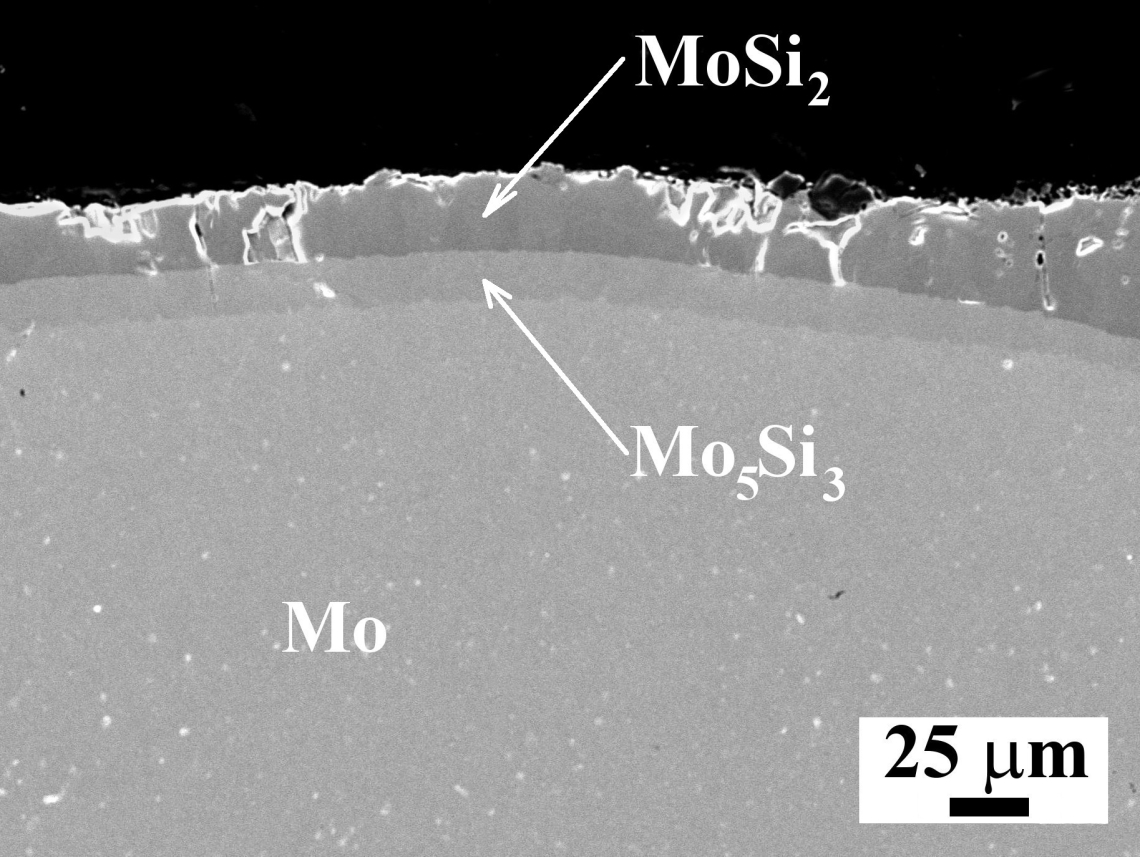

Preparation of functionally graded Mo/Mo silicide composites by reactive infiltration of Mo perform with molten silicon is confronted by two main problems:Mo-Si reaction is extremely intense and leads to the excessive dissolution of Mo perform. Therefore it actually cannot be sufficiently ruled by processing parameters of infiltration i.e. temperature, gas pressure and duration of the process. It appeared, that the most effective way how to get the reaction under control is to limit the amount of silicon available for the reaction. We can adjust the extent of the reaction in this way. Particularly, all the silicon reacts with the Mo perform and forms the required silicides. As soon as the silicon is consumed the reaction is stopped and the composite is formed by high melting point substances- Mo (Tm = 2623 °C) , Mo3Si (Tm = 2022 °C); Mo5Si3 (Tm = 2180 °C) and MoSi2 (Tm = 2030 °C).

Mo-Si reactions during infiltration are accompanied by volume changes resulting into large undesired pores, decreasing the mechanical properties of the composite. These can be partially restrained by secondary compaction using Nb or Ni interlayers. These however react with Mo silicides and form additional phases, (Nb, Nb5Si3, MoNiSi, Ni2Si) with no clear effect on the composite performance.

Achievements

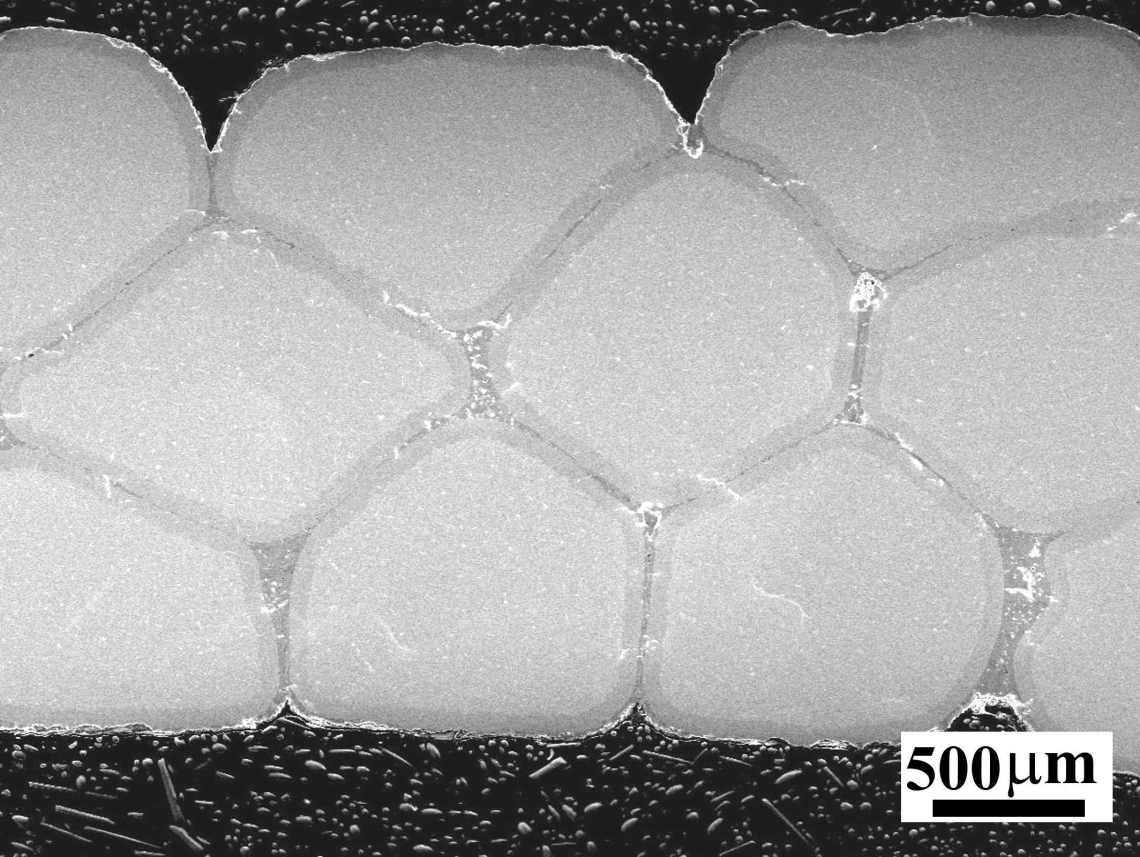

We have demonstrated that the most appropriate way how to obtain the compact structure of the Mo/Mo silicide composite is the pressure assisted reactive infiltration. The composite is prepared in one operation simultaneously bringing together both infiltration and hot pressing. Mo wires are pressed and Si powder in the inter-wire locations is melted in the stressed condition as well. Obviously, there are only narrow gaps between the plastically deformed Mo wires and these are filled with newly formed silicides exhibiting enough plasticity to be deformed and fill the empty inter-wire locations. The formation of excessive porosity is thus eliminated in this way.

Additional reading

SENČEKOVÁ, L. - IŽDINSKÝ, K. - SIMANČÍK, F. - MINÁR, P. - NOSKO, M. - ŠVEC, P. The effect of Nb interlayers on compaction of Mo/Mo silicide composites. In Kovové materiály, 2012, roč. 50, s.425-432. (0.451 - IF2011). (2012 - Current Contents, Scopus, WOS). ISSN 0023-432X.SENČEKOVÁ, L. - IŽDINSKÝ, K. - SIMANČÍK, F. - ŠTEFÁNIK, P. - ŠVEC, P. The Effect of Ni Interlayers on Compactions of Mo/Mo Silicide Composites. In Materials Science Forum, 2014, vol.782, pp. 507-512. ISSN 0255-5476.

IŽDINSKÝ, K. - SENČEKOVÁ, L. - SIMANČÍK, F. - BERONSKÁ, N. - ŠVEC, P. Mo/Mo silicide composites prepared by pressure-assisted reactive infiltration. In Kovové materiály, 2015, vol.53, pp.391-397. (Current Contents, Scopus, WOS ). ISSN 0023-432X.