Advanced technologies / Manufacturing of metal matrix composites /

Monolayers of foils and wires are often prepared in advance using plasma spraying or diffusion bonding to fix the position of wires on the foil. In this case different orientation of fibres in 2D can be obtained.

The diffusion bonding is well manageable through main processing parameters i.e. temperature, pressure and time.

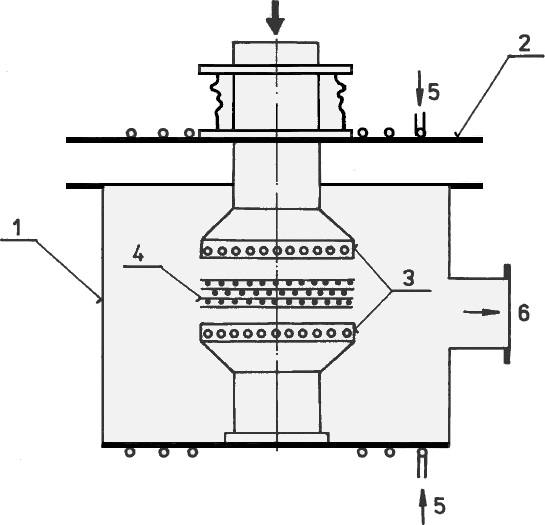

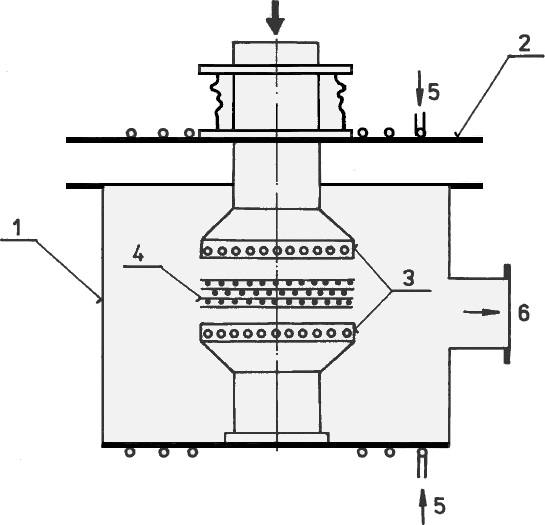

Vacuum chamber for diffusion bonding

Vacuum chamber for diffusion bonding

1 – vacuum chamber; 2 – lid, 3 – preheated pressing tool, 4 - composite perform, 5 – cooling water supply, 6 – vacuum pump connection

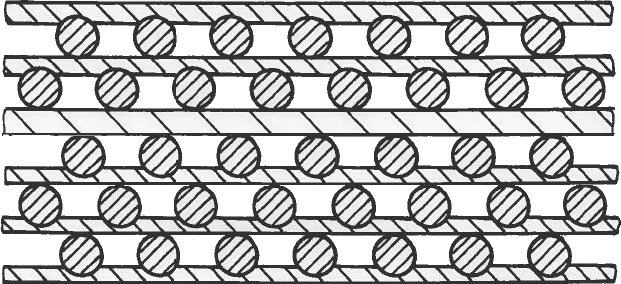

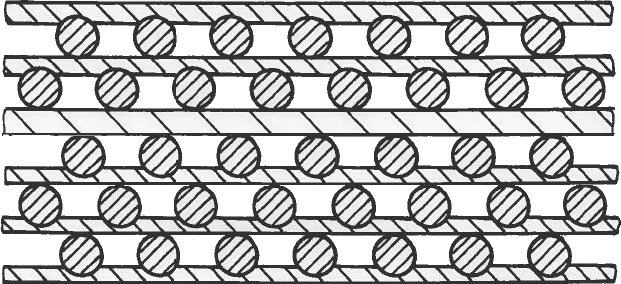

Preform of alternating layers of thin metal foils and wires

Preform of alternating layers of thin metal foils and wires

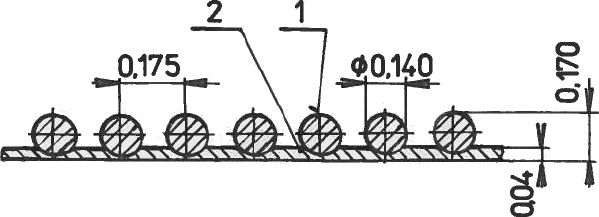

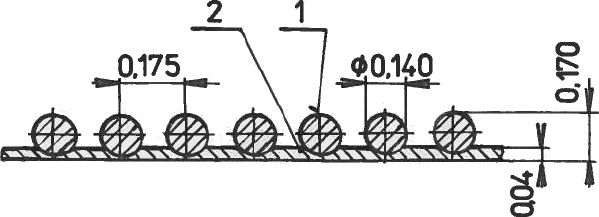

Monolayer of Al foils with B fibres prepared by diffusion bonding; 1 – B fibre, 2 – Al foil

Monolayer of Al foils with B fibres prepared by diffusion bonding; 1 – B fibre, 2 – Al foil

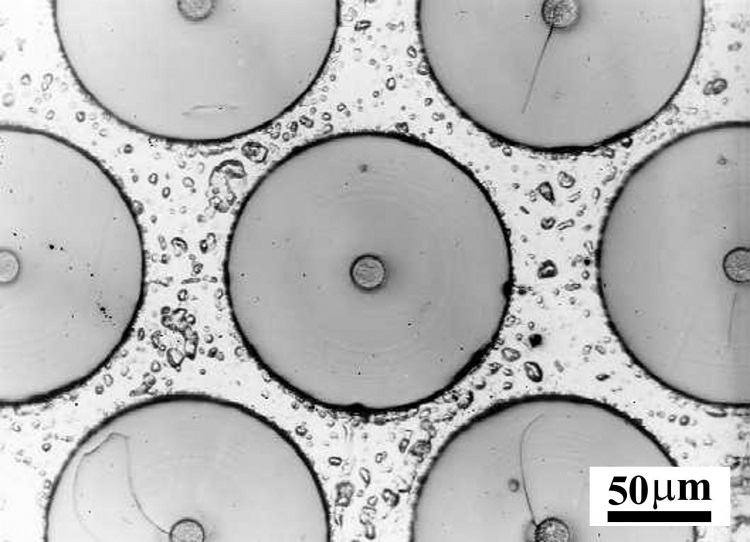

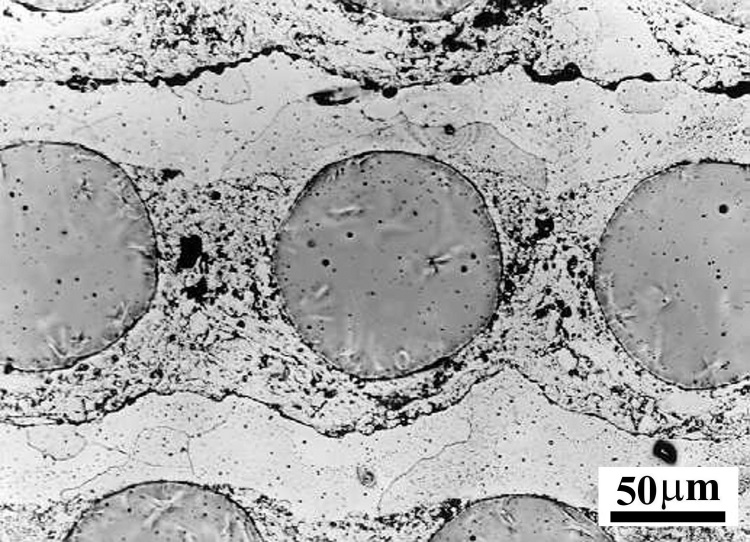

Aluminium matrix/boron fibre composite

Aluminium matrix/boron fibre composite

Aluminium matrix/steel wire composite

Aluminium matrix/steel wire composite

Vacuum diffusion bonding

General description

Diffusion bonding is a solid state technique used for joining of metals or metals with ceramics, etc. It is widely used also for preparation of metal matrix composites (MMCs).Principle of operation

Diffusion bonding operates on the principle of solid state diffusion where the atoms of two solid surfaces intersperse themselves over time. This is usually implemented by applying high pressure, in conjunction with necessarily high temperature, to the materials to be bonded. The process is typically accomplished in vacuum chambers with preheated pressing tools. The technique is widely used to bond preforms of alternating layers of thin metal foils and metal wires or ceramic fibres.Monolayers of foils and wires are often prepared in advance using plasma spraying or diffusion bonding to fix the position of wires on the foil. In this case different orientation of fibres in 2D can be obtained.

The diffusion bonding is well manageable through main processing parameters i.e. temperature, pressure and time.

Vacuum chamber for diffusion bonding

Vacuum chamber for diffusion bonding1 – vacuum chamber; 2 – lid, 3 – preheated pressing tool, 4 - composite perform, 5 – cooling water supply, 6 – vacuum pump connection

Preform of alternating layers of thin metal foils and wires

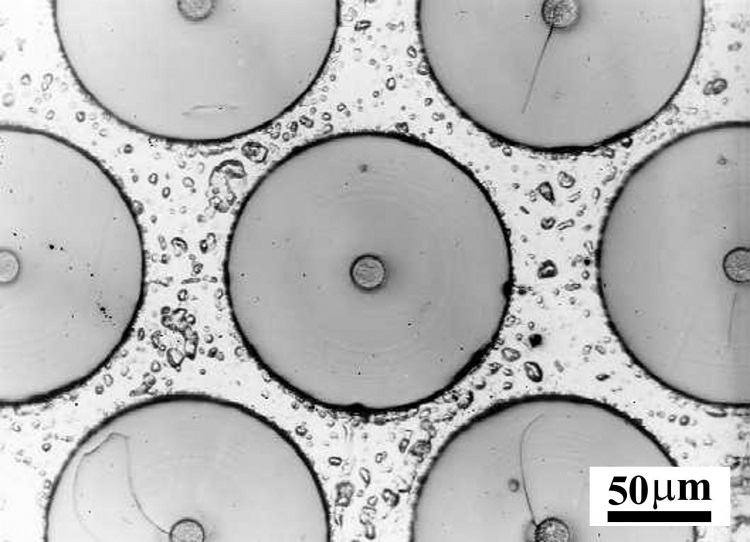

Preform of alternating layers of thin metal foils and wires Monolayer of Al foils with B fibres prepared by diffusion bonding; 1 – B fibre, 2 – Al foil

Monolayer of Al foils with B fibres prepared by diffusion bonding; 1 – B fibre, 2 – Al foilTypical applications

The technique has been successfully applied for the preparation of- aluminium matrix/boron fibre composites

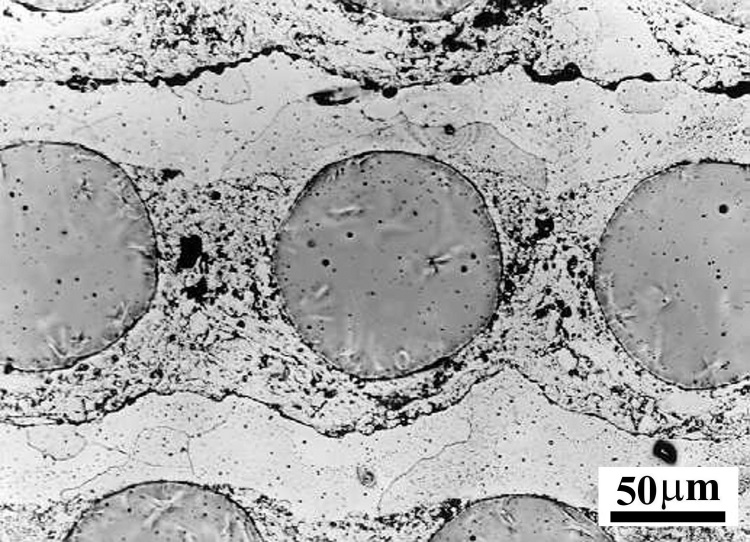

- aluminium matrix/steel wire composites.

Aluminium matrix/boron fibre composite

Aluminium matrix/boron fibre composite Aluminium matrix/steel wire composite

Aluminium matrix/steel wire compositeEquipment

- 300 t hydraulic press

- vacuum chamber with preheated pressing tolls for samples up to 120 x 120 mm