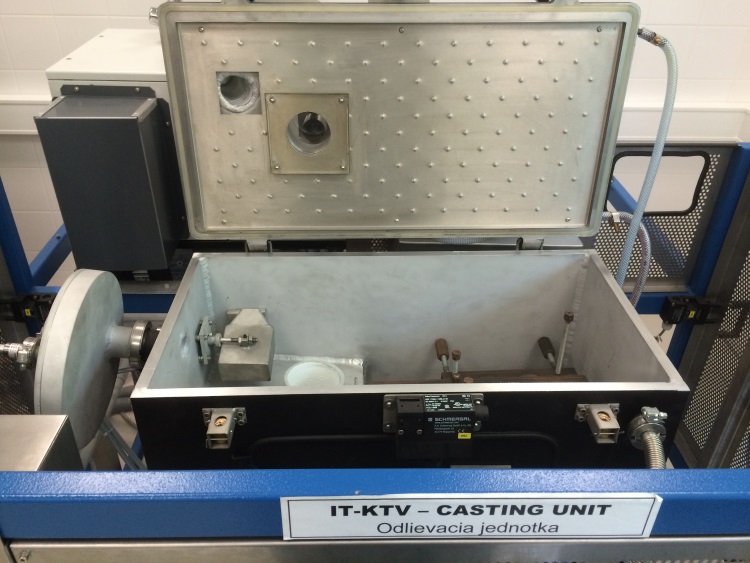

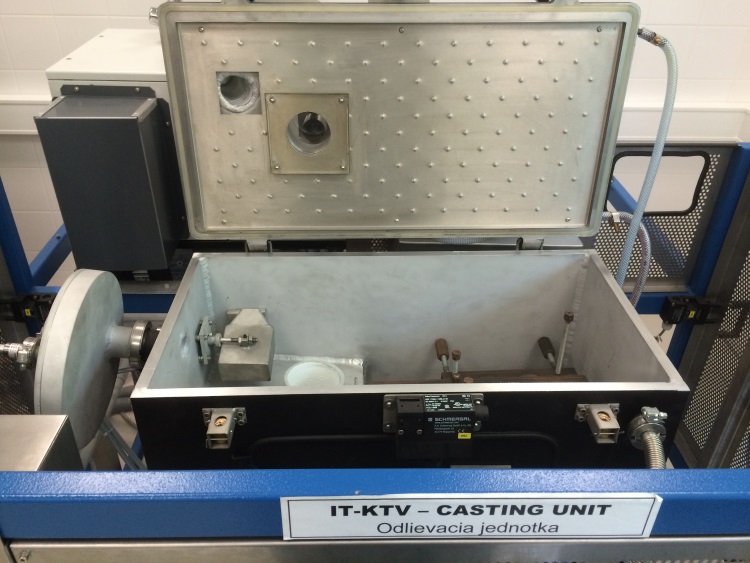

Titanium casting machine Titanium casting machine IT-KTV-20-1.5 (LINN High Therm GmbH) with program controller SE-502 and pyrometer

| Location: | Institute headquarters, Bratislava |

Basic characterization

Investment casting is one of the oldest manufacturing processes, dating back thousands of years, in which molten metal is poured into ceramic mold. It is the most versatile technology to manufacture intermetallic components.

Product properties

- product line - special product

- operation mode -batch

- construction types - melting unit

- designs -crucible furnace, remelting

- temperature max. - 1650 °C

- heatings - electrical

- heating methods - induction

- atmospheres - controlled gas atmosphere, vacuum

- application - melting, remelting

The most important characteristics

- MFG-180 induction generator (180 kW continuous power)

- power output of generator freely adjustable 0.5 - 100 %

- emergency water cooling

- cold wall crucible (no contact of melt with crucible wall or contamination) 0.5 l

- water cooled, gas/vacuum tight chamber with overpressure protection, volume app. 250 l

- lifting device for chamber lid

- pyrometer for melting temperature measurement and supervision

- vacuum pump system for vacuum 5 x 10-5 mbar with rotary vane pumps and oil diffusion pumps

- gas (Ar, N2) purging unit

- controller SE-502

- circulation cooler

Titanium casting machine IT-KTV with program controller SE-502 and pyrometer

Contact

Kateryna Kamyshnykova

Titanium casting machine IT-KTV with program controller SE-502 and pyrometer

Titanium casting machine IT-KTV with program controller SE-502 and pyrometer